A few days later I picked up a big package at

the post office: It contained eight big sheets of Liteply, two

sheets of aircraft grade plywood of the same size, aluminum

landing gear, engine cowling, and a whole bunch of spruce strip

material.

The ready to cover airframe is beautiful !

I would build a model like this again in a heartbeat ! |

First checks...

... in the shop back home: All the parts are cut out, except for

small tabs connecting the parts to the plywood sheets. Some of

the parts had to be picked up on the way between the car trunk

and the shop, because they had already fallen out of the sheets.

The strip material is of good quality as are the aluminum landing

gear, and the engine cowling made of heavy grade clear plastic

material. The “building instructions” consist of a

several DINA4 sheets, with a few drawings, two sheets of locator

plans for the individual plans, as well as two pages of text.

Here it becomes evident, that in order to successfully finish

this project, some previous experience building large wooden models

is required !

A small disappointment, when I saw the edges of some of the parts:

Due to either too high cutting speed or a dull router bit, the

edges were somewhat jagged. Thus the building of my Piper Super

Cub began with the removal and marking of all the parts from the

plywood sheets, and some cleaning up with sandpaper. This produced

a remarkable amount of parts, which promised a lot of building

fun !

As already mentioned earlier, the whole model is built up from

aircraft grade plywood and liteply. This requires the use of old-fashioned

wood glue, in order to achieve lasting strength in the structure.

I only used CA on non load carrying joints. Of course, the use

of slow setting wood glue requires an arsenal of pins, clamps

and strong masking tape.

Fuselage

Once I had all that in place I started on the fuselage: The two

large side panels are joined with the main frames, the lower fuselage

sheeting and the middle decks. This produces a central core, on

which the rest of the structure is based. Spruce longerons extend

the fuselage aft. Here a difference between the planning and material

selection showed up: The slots in the frames were cut for 7x5mm

longerons, however the supplied spruce material was 10x5mm, which

required some work on the frames. The basic fuselage build up

was done in a few evenings.

Tail

Next were the tail surfaces : This is the only area, where “composites”

are used: The tail surfaces consist of foam cores, which are sheeted

with 1.5mm plywood. Once sheeted, using a route, I cut out the

openings, to generate the looks of a built-up, open bay structure.

I then used a scroll saw to enlarge the bays even further, not

as much to save weight, than to make the appearance more scale.

The leading and trailing edges are made out of strips of liteply,

which then have to shaped to the airfoil contour.

The tail surfaces consist of foam cores, sheeted with

1.5 mm plywood, which then are cut out to generate the

looks of a built-up, open bay structure. To improve the scale

appearance I enlarged the cutouts more than lined out in the

plans, also modified the counter surfaces on the elevators. |

Little change on the tail

The plans show all tail surfaces to be removable. However, I prefer

a fixed vertical stabilizer and rudder, with plug-in elevators,

so I modified the design: The horizontal stabilizer was divided

in three pieces. The two plug-in elevators, and an 8cm wide center

section, which was fixed to the fuselage permanently, together

with the vertical stabilizer and rudder. The elevators are attached

to the fuselage with two 6mm carbon rods, and secured with screws,

and of course, the flying wires.

Next are the wings

These are also built up entirely out of plywood and liteply, only

the leading edge is made of hard balsa. Something special is the

one-piece sheeting: the d-box sheeting, rib caps and trailing

edge sheeting are cut from one piece of 1.5mm plywood. The ribs

are made of Liteply, which look very delicate, but also are very

light. The spar is made of vertical Liteply strip, which has slots

for the ribs cut into it.

To begin the building of the wings, the lower sheeting is placed

on the plans. The main spar with is rib slots cut out, is used

as a template to mark the location of the ribs on the lower sheeting.

The spar then is the first thing to be glued to the sheeting.

Of course, when doing this, it is imperative to ensure that everything

is straight and square. Then the ribs are installed and weighed

down, while the glue sets. I installed four ribs at a time.

This procedure rewarded me with two beautiful wing halves, faster

than I had anticipated – two pieces of really nice woodwork!

What really surprised me, was the very small difference in weight

between the to wing panels of only 16g (0.56 oz), with one panel

weighing in at 1,645g (58 oz), the other one at 1,661 g (58.56

oz).

The wing joining system is unusual: It is made of two massive

beech wood dowels, which are glued into the three inboard ribs

of each wing panel, and engage in holes in the root rib on the

fuselage. All the holes in the ribs were undersized, which made

it necessary to painstakingly enlarge them until the dowels would

fit.

Wing tip detail. The wing tip is built up from 20

individual parts. |

Wing struts

The wing struts are fully functional, without them, the wings

will not hold on to the fuselage, even on the ground. The struts

are made of aluminum strip material, encased in pre-shaped spruce

strips. The building instructions include a drawing which shows

what pieces have to be cut from the aluminum for the struts. However,

the fact that on the original, the struts have different widths

caused some additional work, since the supplied pre-shaped spruce

material is of only one size, which required a lot of work with

plane and sandpaper to make the struts to scale. The attachment

fittings for the struts are also made from the aluminum strip

material. This work was performed by my club colleague Michael

Reiser. The fittings are then attached to the airframe with M3

bolts, the struts themselves are attached to the fittings on the

fuselage with M4 Allen head bolts. Once assembled, all this resulted

in a surprisingly tight ant stiff wing-fuselage joint the wings

have absolutely no movement relative to the fuselage.

Landing gear

The main landing gear was a piece of „heavy metal“!

It comes fully assembled, sprung and damped, ready to install.

Unfortunately, at 1,452 g (51 oz) it is also quite heavy. And

later on, I also noticed that it wasn’t exactly to scale,

being 16 mm (5/8 in) too wide. So, again I went to my club colleague

Michael Reiser, who reworked the landing gear to the correct dimensions,

and in the process also lightened it by 284 g (10 oz) !

The landing gear is attached to the fuselage by means of four

M5 bolts, which engage in blind nuts installed in the fuselage.

For wheels, I used the 140mm diameter units from FEMA (www.fema.de),

which are not only very scale in appearance, but also are ideal

for a model this size and weight, due to their design.

Detailing and improvements

Now having finished with the basic framework, it was time for

detailing and improvements. From the beginning, it was my goal,

no to just build “another Piper Cub”, but go new ways

when it came to painting and detailing. Of course for this, first

order of business was to locate a suitable full size Piper Cub,

on which to base my model’s appearance. There are still

hundreds of Super Cubs in active duty, some of them restored,

and maintained with lots of TLC, and others just being used as

workhorses. During my search, I came across the webpage www.airliners.net,

with a collection of nearly 500.00 airplane pictures. It was here

where I found the Piper Super Cub HB-PQM, based in the near of

Zurich (Switzerland), and I decided that this was to be the basis

for my scale Super Cub. Through the photographer, Jerome Zbinden,

I was able to establish contact with the owner of HB-PQM, Hansjörg

Huber. And so it was, that during a business trip to Zurich, I

was able to take measurements of the HB-PQM, as well as take lots

of pictures. During my stay in Zurich, Hansjörg Huber not

only supplied me with lots of additional info and pictures about

the Piper, but also a very nice lunch. We parted company with

the promise, to meet again and fly together, once that my model

would be ready.

Beech wood dowels reproduce the welded steel tube

framing of the original, and are load carrying. |

Once back home, I immediately started to implement

all of the information gathered. First, the elevators: The models

layout has elevators with counter surfaces; the HB-PQM does not.

So I cut off the counter surfaces from the elevators, and glued

them to the horizontal stabilizer. Next, the cabin: The HB-PQM

is a military version, with the square windows, extending further

back than the round-cornered windows of the civilian version,

and it also has the big windows in the roof. Next came the cabin

interior: I decided to replicate the original’s steel tube

structure with wooden dowels. So, I created the structure piece

by piece, and removing in the original structure, as I progressed,

of course keeping an eye on structural integrity at all times.

Eventually, I replaced all the original structure with dowels,

except the two main frames. Maybe later...

Finally, I made a hat rack from balsa, two seats of Styrofoam,

and an instrument panel. The result was already quite appealing,

the “icing on the cake” so to speak. For the future

I plan on more detailing of the interior, installing instruments,

levers, etc.

Full assemble

Finally, in February, the big Piper could be assembled out side

for the first time, in its ready-to-cover stage. A really nice

and big airplane, with a weight of 9kg (19.8 lbs) right on target,

including wheels and landing gear.

Unexpectedly assembling this all plywood/liteply

structure was lots of fun ! |

After eight months of building time, the model is

at the flying site for the first time. I am very satisfied

with the 9 kgs (19.8 lbs) empty weight. |

Here the weights of the individual

components:

Fuselage : 2600 g (91 oz)

Engine cowling : 490 g (17 oz)

Landing gear and wheels : 1650 g (58 oz)

Elevators : 490 g (17 oz)

Wings : 3340 g (117 oz)

Struts :430 g (15 oz) |

Finishing

After thoroughly cleaning up my workshop, it was time

to get started on the finish : Initially, I had planned on using

regular iron-on fabric, however, this idea was quickly dismissed

once I calculated the weight. Next option was AMZ-fabric, a very

tough, paper-like material, which would have to be installed the

old fashioned way using dope. This idea was also discarded, because

of time constraints, and also to avoid problems with the neighbors.

So, in the end, I decided on the proven “Orastick”

covering, made by Oracover (www.oracover.de).

Base color was to be “scale white”, of which 12m (

13 yd ) were required. For the color stripes, I sent a picture

of the HB-PQM to Ines Lanitz, the owner of “Oracover”,

who then sent me the covering in the correct colors.

The rest was routine: Cut the covering to size, clean the airframe,

iron the covering on, and then tighten it with the heat gun. After

one complete weekend, as well as several evenings spent on this

activity, the Piper was ready for installation of the drive train

and radio gear.

Equipement

Eduard Seidl’s recommendation for servos was to use high

quality units with at least 9 kg power. I decided on the HS-645MG

from Hitec. Theses servos weigh 55g (2oz), and have 96 Ncm (135

oz) torque on five cells, and are known for their robust gear

train and electronics. As receiver, I used the “DSQ-12”

from ACT (www.acteurope.de),

which apart from its 12 servo connections also has circuitry incorporated,

which directs the current directly to the servos, instead of routing

it through the receiver’s printed circuit board. A “DPSI-Powersystem”,

as the one I used on my Ju-52/3M, appeared to me as “overkill”.

Two five-cell 1300mAh receiver batteries and a „Safety Power

Switch AW15 DSQ" – also from ACT – completed

the radio gear installation.

Due to the ample space in the fuselage, the installation of all

these components took little time; most of the time was spent

on numerous soldering joints.

Hinge material for the control surfaces was included in Eduard

Seidl’s kit. The control horns, bowden type push-pull rods,

clevises, etc, were acquired from large scale expert Rainer Pfister

(www.fliegerlandshop.de/).

For the elevators, I selected the black/yellow bowden type push-pull

rods from Sullivan. As far as I know, these are the only ones

strong enough, and available in the length I required (130 cm).

I have already used these once, on my Ju-52/3M. For the rudder,

I used a pull-pull system, with plastic covered steel wiring.

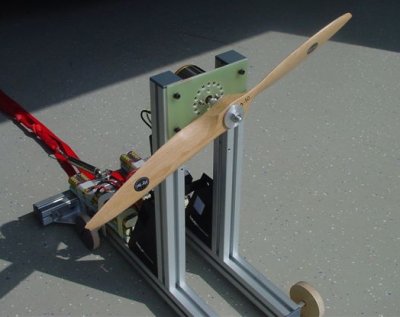

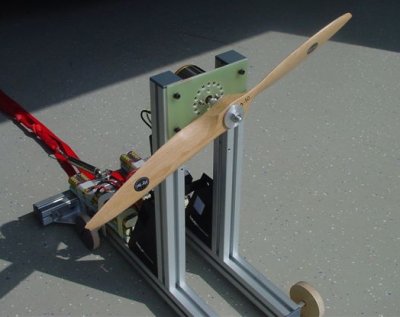

The motor test runs at the Torcman facility in Blaustein

on April 17th provided valuable information. |

Engine

After four weeks of mechanics, the last step to completion, April

17. With the almost ready to fly Piper in the car, I drive to

the village of Blaustein, near to Ulm in South Germany, to visit

Klaus Kraft, the owner of the company Torcman (www.torcman.de),

to pick up the Torcman motor built specifically for this model.

The idea was to receive the motor, and do some run-ups with it,

to assure power output and reliability. So, the motor is installed

on the test stand, and the controller and two 30cell RC-2400 packs

are hooked up. Propeller is a Flytec 26x10” wooden unit.

These propellers are known for their good efficiency and perfect

balance. Once on the test stand, Klaus Kraft slowly applied power.

The motor started smoothly, and he slowly increased power, until

the drive train was running at full power, showing some impressive

numbers: The 26x10” prop was running at 5,100 rpm, on 2.1

kW! During this, the double power pack was supplying 70 amps at

30.5 volts; and after two minutes run time, the test stand was

showing 9.6 kg (21 lbs) of thrust! After six minutes runtime at

different power settings, the power packs were depleted, everything

was shut down, and both of us took a deep breath! We did not expect

this much power, also the whole setup promised to be very reliable,

since after the test run, the motor was only at 70 deg C (158

deg F), and the controller at 55 deg C (131 deg F). So I had no

second thoughts when installing the drive train temporarily in

the model. Once installed, another test run was performed, and

it confirmed this, the drive was running smoothly, without vibrations,

and also, the heat buildup under the cowling remained in an acceptable

range.

The motor mount for the Torcman TM 685 „monster“

motor. Four 10mm carbon rods maintain the distance of 230

mm from the firewall. Later on it is reinforced with diagonal

spruce strips, in order to increase stiffness. |

I now installed the drive train permanently

in the model. The motor, of course is attached to its motor mount.

The controller is placed directly below the motor, immediately

aft of the cooling opening in the cowling. For the two power packs,

a battery tray was made of 4mm plywood, and installed in the location,

where the fuel tank was supposed to be. The power packs can be

removed and installed through a big access panel on the side of

the fuselage. There is enough space in the fuselage, to get both

hands inside, in order to make the necessary connections. With

the power packs moved as far forward as possible, the CG was in

the correct location.

The motor is completely hidden under the big cowling.

The cooling holes in the front were necessary for adequate

cooling. |

The side door allow acces for the 2 cells packs. |

Let's fly!

After a thorough range check, and another short run-up, it was

time: I set the flaps to their take-off position at ten degrees,

and apply power. At 20 per cent power, the big Piper starts moving

down the runway and is easily kept on track with the rudder. Once

full power was applied, it took no more than 20 m (60 ft) to become

airborne, and climb out with a 30 deg nose up attitude! Everything

felt right from the beginning. The model was responsive, but not

too much so, and followed the command inputs exactly. Once it

had reached a safe altitude, I throttled back to approx. 50 per

cent power, and flew a few big circles around the field. A very

scale like appearance !

Ground handling is easy and fun. However, an assistant

is required when installing the wings and struts. |

Control surface

deflections :

Elevator : +/- 25 mm (1in)

Rudder : r/l 65 mm (2.55in)

Aileron s: + 15/-25 mm (+0.6in/-1in)

Flaps : +10°/+70° |

I immediately felt comfortable with the model,

as it flew very smoothly, but still very responsive. And the sound

of the big wooden prop was quite close to the sound of the original.

Also, the model’s air speed made it look very real, and

scale like. Five minutes later, the power packs were nearing the

end of their charge, and I set 70 deg flaps for the landing, which

was uneventful, almost routine.

Everything Okay! So, a little victory dances put an end to the

successful maiden flight. Motor, controller, and battery packs

were just warm to the touch.

The Torcman-Monster motor pulls the big Piper in to

the sky with impressive power. |

The second flight this day was supposed to confirm

the findings of the first flight, but something happened: The

take-off was even a little more powerful than the first, with

the drive batteries delivering their full power, but during the

climb out, a few seconds after liftoff, the motor suddenly quit!

Overload of the controller? Shouldn’t, couldn’t be!

I pushed the big Piper nose down, and let her gain some airspeed,

and retarded the throttle. I then decided to try again, pushed

the throttle stick forward, and to my surprise, the motor came

back to life! I pulled the Piper around in a shallow turn, to

get back to the runway, only to have the motor quit again, this

time for good. And was forced to land the Piper in the field adjacent

to our flying site. To my great relief, once I got to the model,

I saw that it had survived the rough landing without any damage,

and had come to rest just a few feet away from a drainage ditch!

I don’t want to think about what could have happened...

But why had the motor suddenly quit? A quick check revealed the

problem: It wasn’t the motor or controller, but one of the

three 4mm gold-plated connectors between controller and motor,

which had come loose. So, it wasn’t a component failure,

but “human error”, I should have secured the connections

with some shrink tube. Which I have by now, this won’t happen

to me again!

Many successful flights followed. With the two 30 cell packs,

I achieve flights of up to ten minutes, with a sedate flying style,

in calm weather. If the weather is not as calm, or my flight style

is a bit more to show off, flight times will be between six and

seven minutes.

The model’s first public appearance at electro-meet

in Dietlingen near Pforzheim, May 1st. My friend Michael Gerst

assisted me during the flight on the very small airfield. |

I flew the Piper at the electro meet in Dietlingen

near Pforzheim on May 1st, as well as in Traunreut near Lake Chiemsee,

and at the TUN test flight weekend (see www.tun.ch

and AUFWIND 5/2004) in Switzerland. Here it was where I had my

very personal high light: Hansjörg Huber flew in from Zurich

with the full-size HB-PQM, and both airplanes posed next to each

other for the photographers. Of course I had to show off my model

in flight for him, and he, very graciously, invited me to a sightseeing

flight around the Zurichsee in the HB-PQM.

Ready for take off at the TUN test flight weekend

in Buttwil, Switzerland. |

The flight in the original Piper with Hansjörg

Huber was a personal high note. |

This meeting gave me the opportunity to take

some more notes on details, which I plan to incorporate in the

Piper over time. Also, I finally was able to find a 1:3 pilot

figure. Simon Cocker recommended AH Designs from England: Their

1/3 scale pilot figure looks very nice, and weighs only 88g (3.2

oz).

Finally I can say: The HB-PQM is my model for

the new season. The plywood construction makes the model very

robust and able to handle the wear and tear of frequent use. Due

to the tough plywood sheeting, nicks, dings and scratches are

not much of an issue. Ground handling also is a joy. Just the

„loading“ of the model with two 30 cell packs is a

show all by itself!

| The real plane, witch the model is based

on, flying over the Aspach airfield. |

Fact

Box

Designer

: Eduard Seidl

Distributor : MMB-Müller

Modellbau

Wing span : 3.600 mm (141 in)

Length : 2.300 mm (90 in)_

Flying weight : 18.100 g (39.9 lbs)

Motor : TM 685/30 14pole 18turns by Torcman

Controller : "Master MAX", Hacker

Drive battery : 60x Sanyo RC-2400, in 2 30 cell packs

Propeller : Flytec 26"x10", wood

Current : 70.5 A

Flight time : 8 minutes |

|